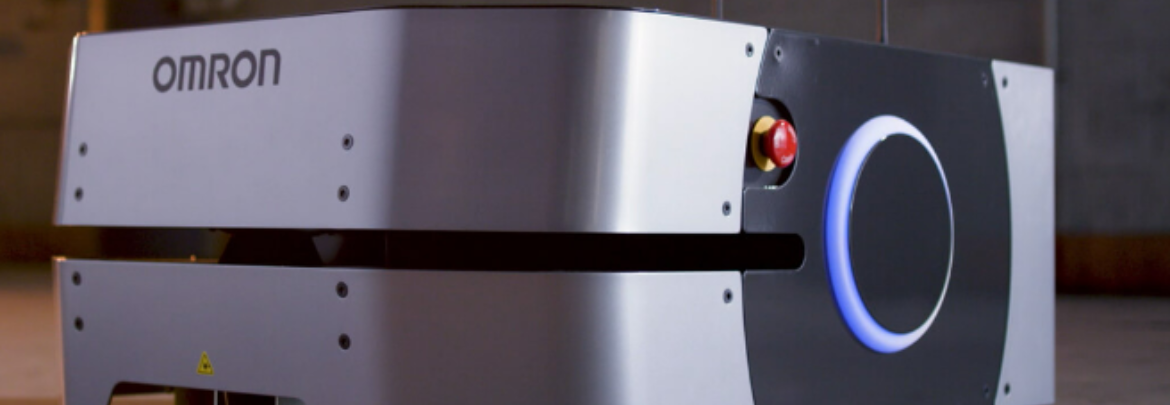

As demands for faster production and efficient manufacturing processes continue to rise, businesses are seeking innovative solutions to conquer these challenges. One of these solutions is the use of Autonomous Mobile Robots (AMR). These intelligent machines can function and move independently, without requiring human intervention, while delivering numerous advantages for manufacturers. In this blog post, we explore the benefits of utilizing AMRs and offer a guide on how to measure the return on investment for these investments.

Improving Efficiency and Productivity

The most apparent benefits of AMRs are the improvements made in efficiency and productivity. With robots that can move and function autonomously, manufacturers can easily carry out repetitive and time-consuming tasks, such as picking and transporting goods, allowing employees to focus on more complex responsibilities. AMRs can navigate effortlessly in vast and cluttered workspaces without the need for fixed conveyors and edging, eliminating the need for human effort and reducing the risk of injury in the workplace.

Enhanced Accuracy and Precision

AMRs are equipped with modern LIDAR (Light Detection and Ranging) technology and sensors that provide improved precision and accuracy, making them useful in delicate tasks requiring accuracy and efficiency. They can avoid obstacles, detect and respond to other robots or humans, and stay on their designated path with unmatched consistency, with no deviation from their standard operations.

Saving Time and Cost

The use of AMRs can help cut down operational time and cost. Automated operations with robots are quicker and more efficient, implying that manufacturers can produce more output in less time, optimizing production rates. Also, the use of AMRs reduces the need for human intervention. Therefore, businesses can cut down on labor costs, as there will be no need to pay for labor for mundane and repetitive tasks.

Enhanced Flexibility and Scalability

Businesses operate in an environment that is continually evolving. Therefore, manufacturers need to keep up with the changing demands and trends in their industry. AMRs help ensure manufacturers scale and adapt to changing production requirements and workloads seamlessly. Manufacturers can easily adjust schedules, workflows, and even increase production during peak seasons, reducing delays and enhancing customer satisfaction.

Measuring the Return on Investment (ROI)

To measure ROI on investing in AMRs, the first step is to calculate the entire cost of the investment, which includes purchase cost, installation, and configuring the software and staff training. Then, determine the time-frame for the investment to compensate for the initial cost. Finally, the accumulated benefits of adopting AMRs – including improved accuracy, efficiency, and productivity, reduced costs, as well as enhanced flexibility, scalability and even worker safety – can be measured for the determined period after the investment. The amount saved by reducing labor costs, human error, and improved production rates usually determines the ROI of AMRs in the manufacturing process.

The use of autonomous mobile robots revolutionizes the manufacturing industry by providing unparalleled solutions to long-standing challenges. Autonomous robots provide scalable, efficient, and accurate solutions that businesses can rely on to achieve their production goals. The benefits of AMRs include improved safety, enhanced efficiency, increased scalability and flexibility, as well as reduced costs. Measuring the return on investment is key to unlocking the potential of autonomous mobile robots, and the most efficient method to measure ROI is to calculate the investment’s comprehensive cost and the benefits of automation, operational efficiency, and worker safety. AMRs progress continues to reveal automation’s potential for businesses seeking real-time problem-solving solutions while also remaining cost-effective.

If you would like to learn more about AMRs, our Robotic Engineering team is available to help. You can email us here at [email protected] or call us at 800-844-8405.