Sawyer has been designed to increase performance and adaptability

What is a collaborative robot?

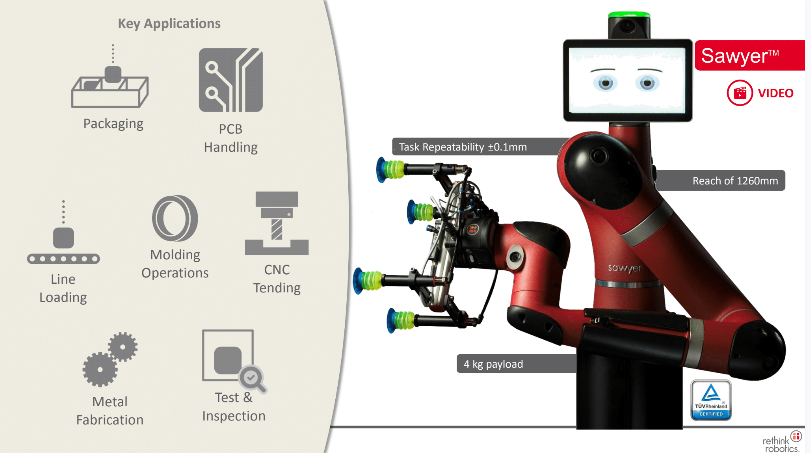

If you look up collaborative robots on the internet, there are variations of what it is. The literal definition of collaboration is The action of working with someone to produce or create something, which is the exact purpose of collaborative robots. Most people would think a collaborative robot is a robot that is used without fencing and can work around humans. Well, yes, this makes it collaborative, but no, it does not make it a collaborative robot. Sawyer is a single-arm 7-axis collaborative robot with the same software and features as Baxter, capable of handling more payloads with increased accuracy.

Power and Force Limiting

Only one type of collaborative robot can be used without additional safety features. This type features power and force limiting and can work alongside humans without other safety devices. The cobot can feel abnormal forces in its path. It is programmed to stop when it reads an overload in terms of power. These robots have also been designed to dissipate forces in case of impact on a wide surface, which is one of the reasons why the cobots are rounder.

Immediate Response

The main feature of cobots is their ability to read forces in their joints. This allows them to detect when abnormal forces are applied to them while they are working. In these situations, they can be programmed to stop or sometimes reverse positions mitigating the initial contact. This means they can respond immediately if they come into contact with a human and even dissipate some of the energy transferred from the impact.

How Do You Train a Cobot?

In the case of Sawyer, the arm “gives” when it encounters an obstruction and it will pause then proceed to continue its task. If it encounters an obstruction again within a short period of time, it will stop and put up an error notification and wait for an acknowledgment. Another interesting feature, hand guiding, allows you to “train” the cobot a task vs. programming through a complicated language. In fact, since these robots can feel forces, you can literally move them and show them positions or paths that they can repeat afterward. While hand guiding helps with human-robot collaboration and ease of deployment, it does not make the robot intrinsically safe. The force limiting features are mechanically designed into the system with patented force sensors do this.

Easy Programming and Integration

Economically, a force-limited robot is ideal because of its easy programming and integration. When you think about it, there is no need for fencing or other safety devices, (however a risk assessment should be performed) since the programming time is reduced. You don’t need to change your production line since it is made to work alongside humans. Manufacturing robots used to be limited to high speed, high cost, and hard-guarded applications separating the machine/industrial robots from the operators. This focused deployment on high-volume applications. Today, smaller companies with multiple short-run processes can utilize these easy-to-deploy robots, and move them from task to task as needed.

We also see a collaborative robot as interacting with its human counterparts on the line – by being simple enough for non-engineers to train it by hand, communicating its understanding of the task, illustrating where it’s going next, and other behaviors that help make it just another coworker/Cobot on the line. These solutions allow for companies to keep and grow existing employees providing them opportunities to grow within the company as the collaborative robots are deployed as a tool that automates many tasks companies are struggling to find people to perform.

If you have an interest in collaborative robots or would like to know how easy it is to integrate them. Please contact Sure Controls. We look forward to making you smile.