Temperature Control Success: Film Tech, a company in Stanley, WI, purchased a used 3 layer blown film line from a company in Ohio. The machine was disassembled and brought to their facility in the spring of 2015. Film Tech requested that a complete controls upgrade be completed on the line due to lapses in documentation for the machine in its original state. The scope of the project was focused on upgrading the temperature control of the extruders and die, updating the web handling of the line with new drives and motors while providing a new operator station to control the line processes. With these items, updates to the safeties on the machine were also necessary. The upgrade required not only electrical support for the items that Sure Controls was providing, but also interfacing the equipment to the new Process Control Corporation (PCC) and QC Electronics equipment. Aside from the electrical support, mechanical support was also to be provided for motor mounting, a new chill roll, winder improvements as well as aiding in the location for control cabinets and conduits.

Solution

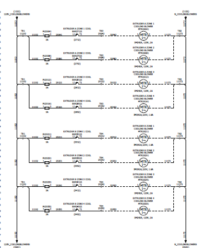

The portion of the upgrade that focused on upgrading the temperature controls required replacing the old system with new Eurotherm 3216 controllers to be mounted on the control cabinet on the 2nd floor. Each heating and cooling section on the ground level would be enabled with Carlo Gavazzi Solid State Relays in the main control cabinet. Separate conduits were run from the control cabinet to the junction boxes on each of the extruders to provide separation of the high voltage wires from the signal wiring for each section. From the new Wonderware station, the operator would be allowed to adjust temperature set points and observe temperature feedbacks from the thermocouples installed at each section. Current Transformers were also installed on the SSR’s to provide current feedback to the HMI. This feedback along with the temperature controller output percentage can be used as a great troubleshooting tool to determine if a heater is not functioning properly.

To improve the web handling of the machine, the old DC motors and drives were removed. The drives were replaced with ABB ACS880 VFD’s. For the Extruder motors, Baldor motors were used as the physical sizes of this option was more favorable than the Marathon Black Max motors that were used on the line drives. The line drives (Top Nip, Cooling Roll, and Spindle Drives) were sized with 3 HP drives to keep the amount of spares to a minimum, one spare drive could replace multiple on the machine if needed. The Winder Nip line drive remained as 1HP, but the motor and drive were also replaced. One request from the customer was to go larger with the Spindle motors to give them the ability to run faster. Due to the mechanical limitations on the bearings, gearboxes, belts, pulleys, and clutches, we kept the original equipment in place. If it is determined that the Spindles need to go faster, the mechanical restrictions would need to be addressed at that point.

To improve the web handling of the machine, the old DC motors and drives were removed. The drives were replaced with ABB ACS880 VFD’s. For the Extruder motors, Baldor motors were used as the physical sizes of this option was more favorable than the Marathon Black Max motors that were used on the line drives. The line drives (Top Nip, Cooling Roll, and Spindle Drives) were sized with 3 HP drives to keep the amount of spares to a minimum, one spare drive could replace multiple on the machine if needed. The Winder Nip line drive remained as 1HP, but the motor and drive were also replaced. One request from the customer was to go larger with the Spindle motors to give them the ability to run faster. Due to the mechanical limitations on the bearings, gearboxes, belts, pulleys, and clutches, we kept the original equipment in place. If it is determined that the Spindles need to go faster, the mechanical restrictions would need to be addressed at that point.

In order to operate the Winder, a 9” Redlion Graphite HMI was mounted on the winder to allow the operator to control the Winding Modes, such as Winding on the top or bottom, over or under mode, engaging the lay on rolls, opening/closing the Winder Nip while providing Line Diagnostics for the Emergency Stops on the Line. The layout and color schemes on the winder HMI mimicked the Main Operator Panel which has a 19” Touchscreen with Wonderware. This main operator panel allowed for a central location to control the temperature set points on the extruders and die, the line speed, as well as auxiliary controls such as the Oscillating Haul Off, Bubble Cage and Treater. Trend screens were provided to allow monitoring of temperatures, speeds and other line characteristics which could help in diagnosing defects in their products. The Wonderware station was setup to communicate to the PCC blenders and vacuum loading system. From the MOP, the vacuum loading system could be completely controlled by enabling/disabling hoppers, while the Blenders control was slightly restricted. The Blenders could be toggled off or into auto mode, however if any manual action was needed to take place, this control was left off the MOP to require the operator to be within sight of the blender. Hopper Weights, Blender Status’s, and Throughput (lbs/hr) were all brought to the HMI for trending/monitoring purposes.

To provide the operator with a safe environment to work, the machine had an Allen Bradley Control Logix Safety PLC installed. With the use of Allen Bradley Point IO, safety racks were installed at each level of the machine to provide the operator with the ability to shut the machine down with various safety devices, such as lifelines, emergency stop pushbuttons, safety mats, and safety scanners.

Continued Support

With the main solution in place, additional service was requested to address a few items on the line. One of these was the addition of automating the A-Frame at the Top Nip. This required the placement of 4 servo motors on the Top Nip and additional logic to be added in the Control Logix Processor. The operator would enter a desired distance between the sides on the A-Frame and press Go to Position pushbutton on the HMI. Analog signals from internal potentiometers inside the Servos were brought back to the PLC and scaled so an accurate position feedback could be displayed to the operator. The control for this was provided on the Main Operator Panel, but an additional 9” Redlion HMI was programmed and supplied to Film Tech to provide the operator with the ability to control the A-Frame Adjustment from the Top Nip.

In addition to the Top Nip changes, there was a desire to improve the existing IBC system on the line. During the trials runs conducted at Film Tech, the film had wrinkles. The wrinkles were thought to be caused by the IBC system not controlling proper pressure on the inside of the bubble causing the film to surge. New ultrasonic sensors and a Eurotherm 2704 controller were used to replace the existing equipment inside a new IBC cabinet. On the door of the IBC cabinet was 3 potentiometers to control the speed of the Supply and Exhaust Powerflex VFD’s. A large control valve was also supplied to restrict the amount of air leaving the bubble. With the new controls in place and some tuning, a stable bubble was produced, solving the wrinkling issue.