Extensional Viscosity – Rheological Significance of the Entrance Pressure Drop

Azadeh Farahanchi, Rheological Scientist, Ph.D

Extensional/elongational viscosity measurements (melt strength) are of rheological importance in any plastic stretching process for example blow molding, sheet extrusion, blown film extrusion, fiber spinning, etc. as the plastic is constantly stretching or expanding in such processes. Two polymers may have same shear flow behavior, however they may show different extensional flow behavior depending on their molecular structure, branching, etc.

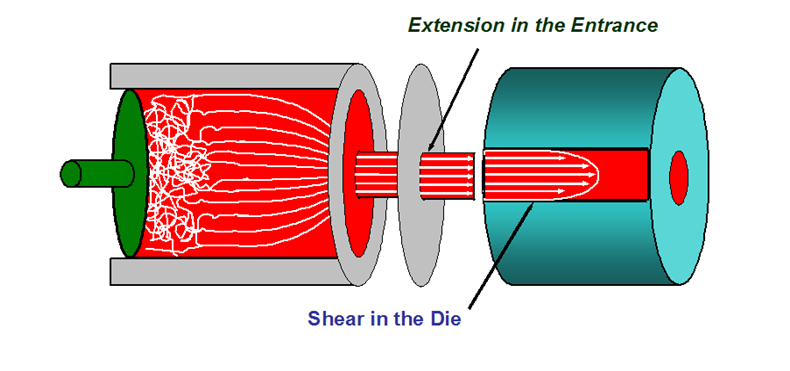

In a capillary rheometer, the polymer melt stretches along the streamlines at the entrance to the die since the diameter of the die versus that of the barrel is very small. The picture below illustrates the flow of polymer melt from the barrel of a capillary rheometer to the orifice die. The polymer melt faces extensional deformation during transition at the die entrance. Capillary Dies with smaller diameter or larger entrance angle increases the amount of extensional deformation.

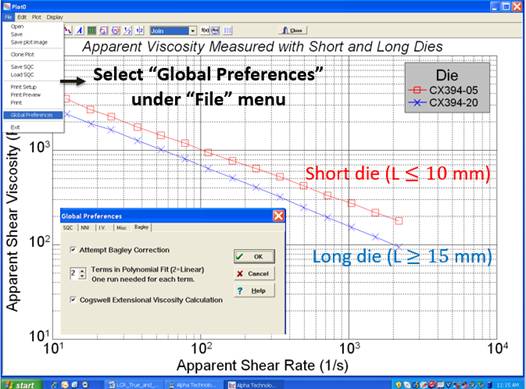

Dynisco® capillary rheometer (LCR) uses Cogswell`s equations [1,2] and calculates the extensional viscosity of polymer materials at wide range of extensional rates (specifically the rates which correspond to those in a plastic processing line). For this purpose, the rheometer needs information on the amount of the entrance pressure drop which happens due to the elasticity nature of polymer materials. The entrance pressure drops and extensional properties can be calculated by performing two shear sweep tests on the rheometer using two different dies which have same diameter but different lengths.

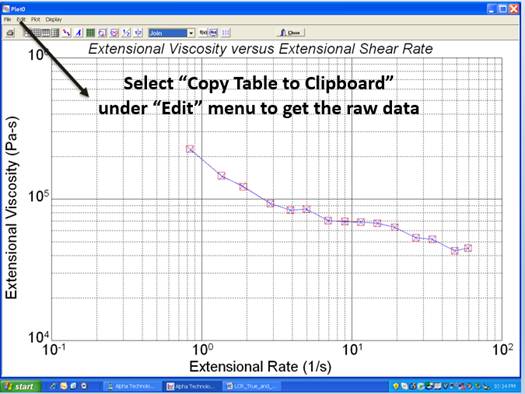

By obtaining the figure on top one can analyze the extensional viscosity level of the material and whether it is increasing or decreasing with extensional rate.

REFERENCES

- F. N. Cogswell, Trans. Soc. Rheol 16:383 (1972).

- F. N. Cogswell, Polym. Eng. Sci. 1:46 (1972).