The Problem:

Your profits are off – costs must be lowered

-

- Your efforts miss the mark when they focus on areas that don’t deliver the needed return on the investment.

- Initiatives are launched by guessing where the real problems are in your manufacturing process.

- Data is costly to collect.

- Accuracy is suspect.

Bottom Line: Waste in the plant lowers profitability and puts the plant at a competitive disadvantage by higher costs. Work is shifted to more productive plants or to the competition further reducing profits.

What happens:

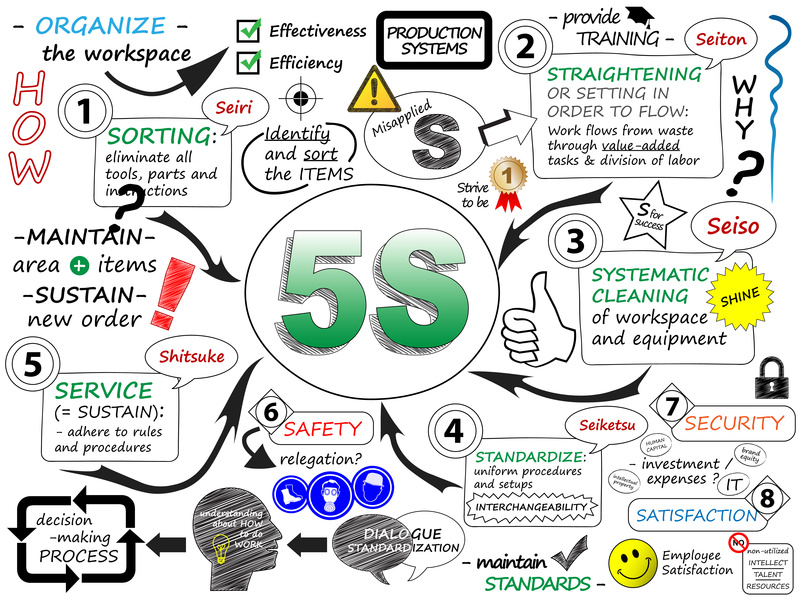

Leadership launches initiatives like Overall Equipment Effectiveness (OEE), Lean or 5S but still don’t get the return needed to recover the investment, lower costs and become more competitive.

Initiatives become ‘flavors of the month’. Eventually programs are dropped and costs remain excessively high. The plant is closed.

Solution:

Knowing where you are and where you want to go are essential to achieving world class manufacturing standards like OEE. Sure Controls offers automated data collection solutions including Easy Start to give you the information to target your cost reduction where the larger rewards may be captured.

Result:

One customer installed Easy Start on one machine. The savings in manual collection justified the installation in less than a year. In that first year focused cost reduction returned 7% improvement in waste reduction. Installations are underway across two plants.

Just call your Sure Controls sales representative to discuss your application – (800)844-8405