Flexible Feeding Systems for Manufacturing Automation

Flexible feeding systems improve automated feeding solutions by handling a variety of parts with minimal adjustments. These flexible part feeding systems reduce downtime, increase efficiency, and integrate easily with robotic feeding systems. Used in industries like automotive, electronics, and consumer goods, they enhance precision and streamline production.

Key Benefits of Our Flexible Feeding Systems

- Increased Efficiency – Speeds up part handling and improves feed rates, keeping production lines running smoothly.

- Flexibility – Adapts to different part shapes and sizes without major reconfiguration, making it a versatile feeder system.

- Reduced Labor Costs – Automates part feeding, lowering reliance on manual labor and improving consistency.

- Improved Precision – Enhances accuracy in part positioning, reducing errors and waste with advanced vision systems.

How Flexible Feeding Systems Work

Flexible parts feeders sort, orient and deliver parts for manufacturing with minimal adjustments. Unlike traditional industrial feeding systems that require custom tooling for each part, these solutions use vibratory feeders, belt conveyors, and vision systems to efficiently handle different shapes and sizes.

Integration with Robotics

These flex feeders work alongside robotic feeding systems, pick-and-place machines, and vision technology to identify, pick, and position parts with precision. This reduces errors, increases efficiency, and allows for quick changeovers between different parts.

Industries Served

Flexible part feeding systems are used in a variety of industries:

- Automotive – Handling different components on assembly lines.

- Electronics – Feeding small, delicate parts accurately.

- Medical & Pharma – Ensuring precise, contamination-free part handling.

- Packaging – Sorting and packing products quickly and efficiently.

By adapting to different production needs, flexible part feeding systems help manufacturers improve efficiency and reduce downtime.

Solutions Offered by Sure Controls

Unleash Efficiency with Flexible Feeding Systems

Flexible parts feeders eliminate common production bottlenecks like jamming and misalignment, helping manufacturers boost efficiency and precision.

By combining the Asycube, Asyfill smart hopper, and the EYE+ smart control system, you can improve feed rates and achieve a rapid return on investment.

Product Features

Our automated feeding solutions are designed for adaptability and performance, offering:

- Customization Options – Configurable settings to handle a wide range of part shapes and sizes.

- Scalability – Easily adjust system capacity to match production demands.

- Seamless Integration – Compatible with robotic arms, vision systems, and automation controls.

- Durable Materials – Built with stainless steel and high-quality polymers for longevity and reliability.

Types of Flexible Feeding Systems

We offer a range of flexible feeding solutions tailored to different manufacturing needs:

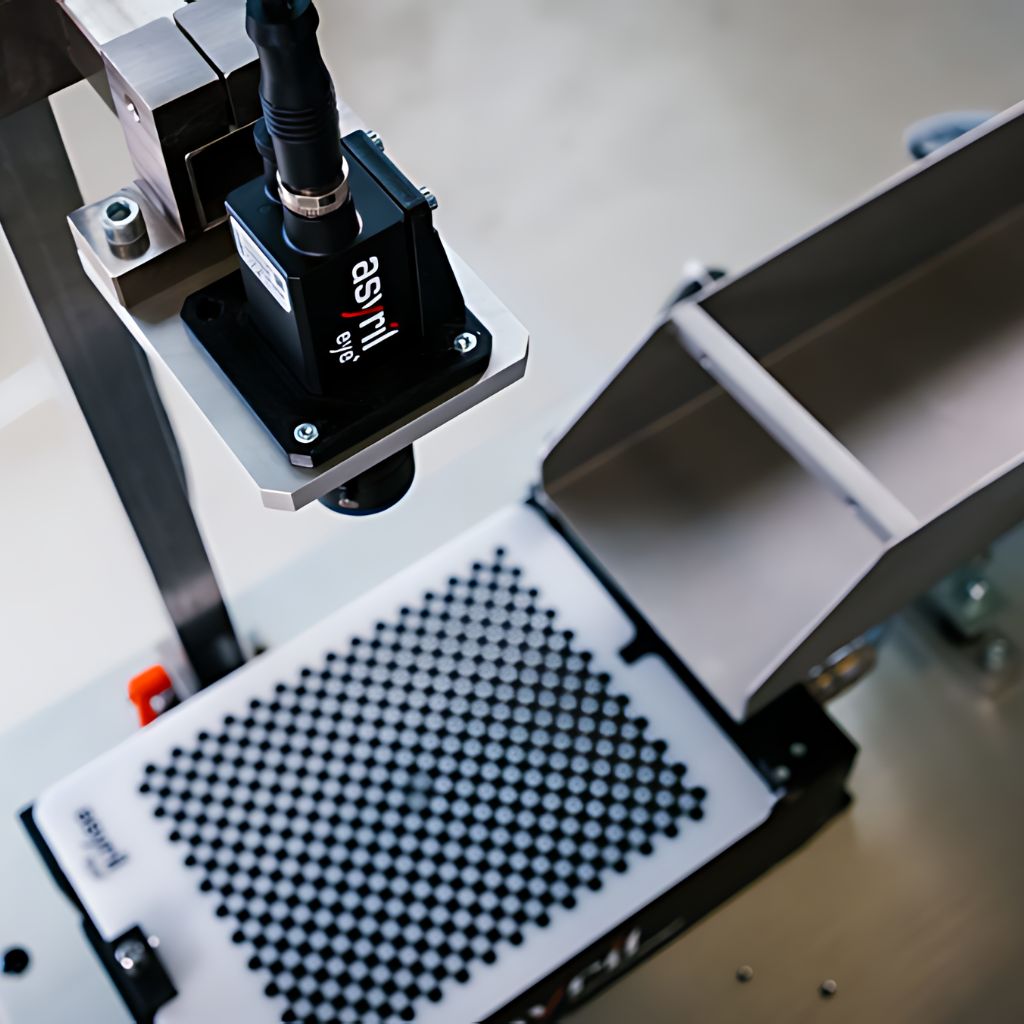

- Asycube – Uses finely tuned vibrations to manipulate and orient parts with precision.

- Asyfill Smart Hopper – Ensures a steady supply of parts for uninterrupted production.

- EYE+ Smart Control System – Provides real-time part recognition and intelligent automation.

Optimizing Your Production

When you partner with Sure Controls, we help you build the right flexible parts feeding system for your production line, ensuring:

- Reduced Costs – One feeder system handles multiple parts, minimizing additional equipment needs.

- Increased Scalability – Systems can be expanded or modified as production needs change.

- Improved Efficiency – Fast, precise part feeding, even for delicate components.

Watch Flexible Feeding Systems in Action

Explore our flexible feeding system videos to see how our solutions can transform your operations.

Looking for Asyril Solutions?

Have a Question?

Talk to a company that understands manufacturing and what it takes to automate your process.